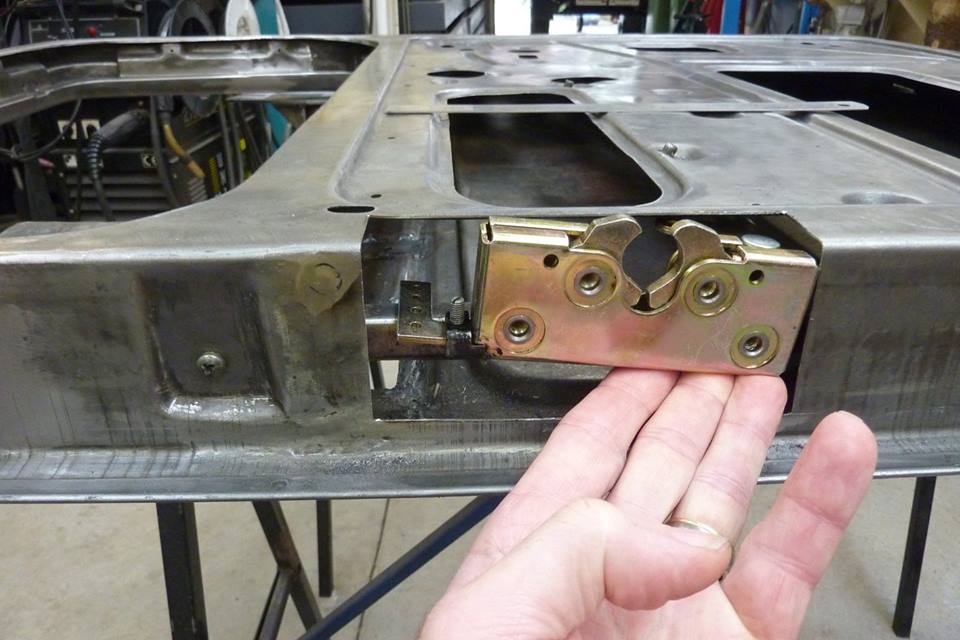

Bought a new bear claw door latch kit to update the nearly 60 year old stock ones. Was hoping to use the donor Jeep ones, but they were just way to big to fit. These come in a small and large styles, but chose the large which is recommended for heavier doors as has more latching strength.

The position was same as stock centering on the B pillar recess. It will fit over the old location in the door as well.

Will have to find a way around the interference of the locking lever with the window channel.

The large and small styles are both the same thickness at 19mm- 3/4". Will have to hammer out the side of the door a bit to make sure it clears.

The mounting plate is is fully welded into position.

Just showing on the other door how I pre-tensioned the door by clamping down onto the trestle before welding it. The shrinkage of the welding brought it back flat again along the back of the door.

Smoothed off. You barely notice the extra couple of millimetres to clear the window channel as I made sure the folded edge was still straight and inline with the rest of the door.

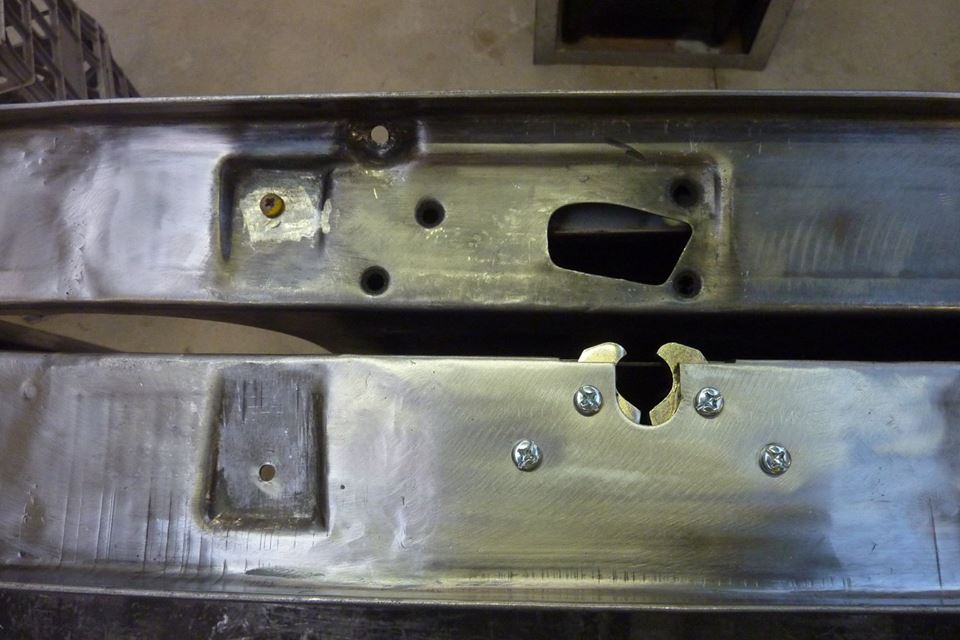

Here you can see the differences and the modifications needed. I hammered out the old recess for the exterior handle mounting screw and also deepened the one side of the pocket for the window channel mount.

I had done this by making this little hammer form to match the shape I wanted in the end.

The form was placed on the table and the door clamped over it. The edge was then hammered down. A mallet was also used inside the door to hit down on top of this hammer.

Can see the shape finished now.

Can't say I was that rapt in the way it mounts with the jaws protruding past the door edge when open.

It also meant the striker bolt mount would be partially off the edge as well on the B pillar as well as the caged nut on the back.

So I welded up the mounting holes and made the front opening hole smaller as well. Moved the whole lock back further inside the door. This also solved the clearance problem with the locking lever as well as more clearance for the opening and closing release latch as well.

I couldn't use the recess as then the striker bolt would not reach the new lock.

So it was cutout completely so that the new mounting plate with the nut cage with nut could be butt welded into place. The top and bottom edges were arched outwards slightly so that the weld shrinkage would pull it inwards.

Good full penetration welds, rather than weak little tacks all over the place, was used to weld it into place. Pre-stretching the edge meant it pulled back flat after welding as no hammering could be done.