Well, the exhaust cannot run out the middle as per the factory centre outlets of the SRT model that the system was made for. I still had the factory single stainless system which is the same diameter, 70mm-2.75", as just one of the new pipes.

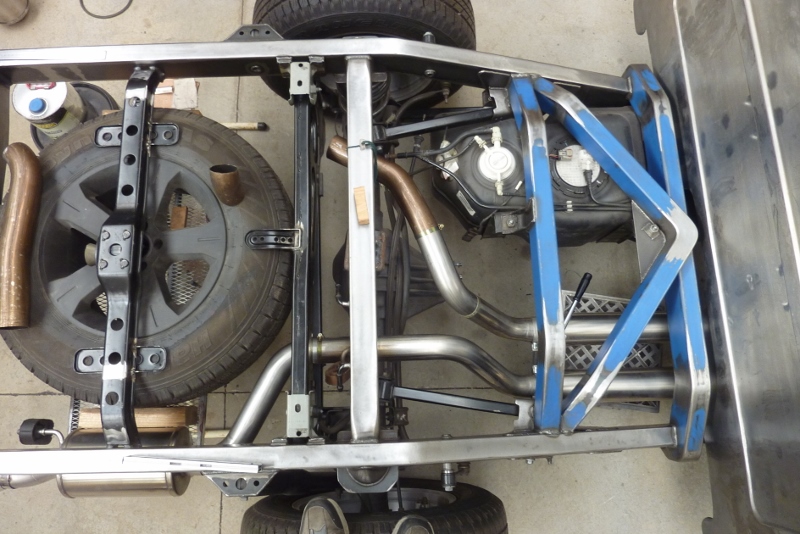

Re-routing the right side was easy as I only had to cut and flip the exhaust over. I used the left side dogleg instead as it reached over further to where I wanted it.

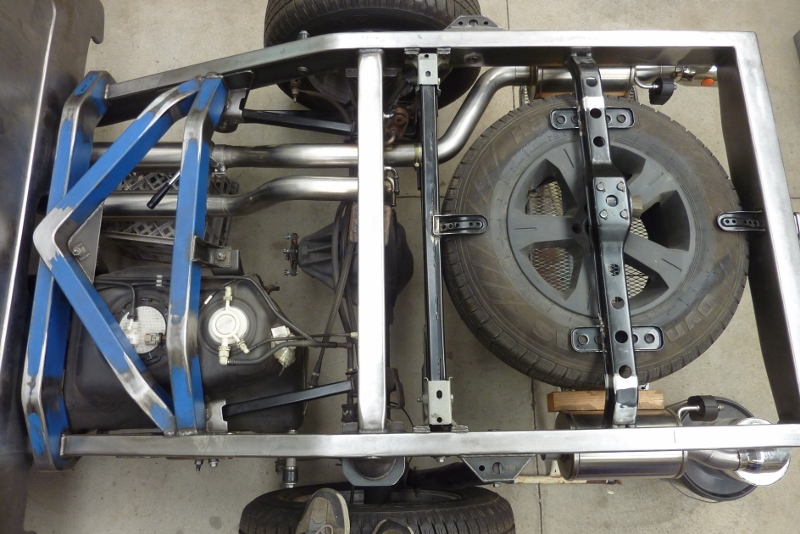

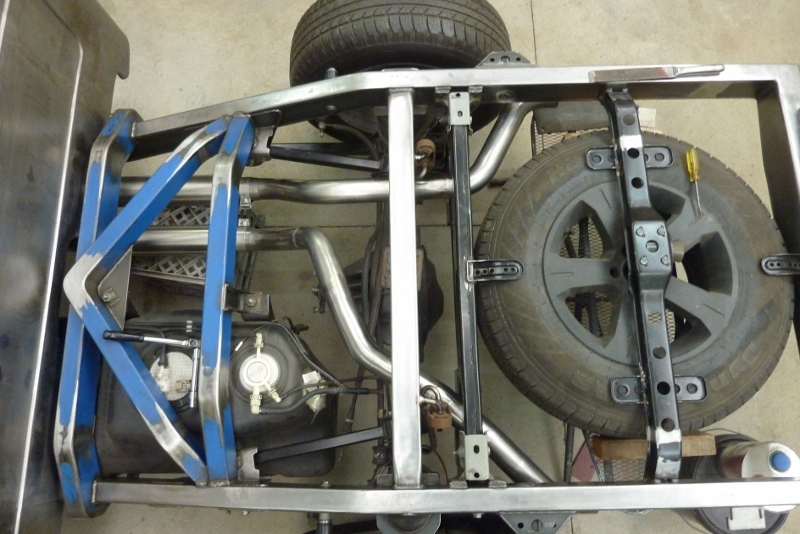

It looks odd sitting out that far at the moment, but the chassis had been narrowed to fit the donor suspension in the right place. The bed will actually be wider than stock and cover the rear muffler and will be behind the frame skirts.

So with the muffler on the left placed to match the other side, I just have to get it across. First have to clear the pinion flange, top of the diff and sway bar at full suspension compression. Then turn before hitting the left side upper control arm bracket, under the cross member before going through a hole in the next, miss the shock absorber and then line up with the back of the muffler!

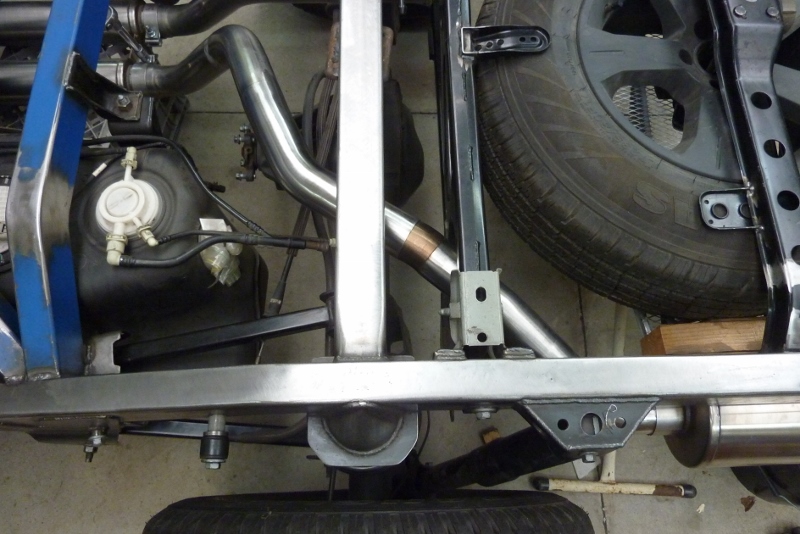

I cut the exhaust off just before the last bend and also found a section from the original system that lines up with a hole in the panhard bar support cross member and the muffler. Just have these bends left to complete the system.

Using one of the bends from the right side dogleg and the rest of the original system gets me pretty close. I am just using hose clamps to keep things in place while mocking up.

I am just going to fuse weld the system together using the tig. 1.6mm-16 gauge lanthanated tungsten to match the same gauge tubing wall thickness.

I just draw a straight line using a ruler over the hose clamps before disassembly. Better than small marks as you can make sure the line is still straight after tacking in case it wasn't butted up square.

I have used a paint strip disc to clean the old stainless and also the welds. If you don't clean the welds, either mechanically or with acid to pacify them, it will rust there.

Just had to meet the two sections together between the cross members. Needed a slight bend. I measured the furthest and narrowest side of the gap and found a bend that would match it. I used hose clamps as a guide to draw my cut lines around making sure they match the smallest and largest measurements.

The bend lined up first go using this method so will tack it in place in situ to make sure it all lines up after welding.

Have the two hangers in place with two more to go after the mufflers. It worked out better than I expected actually as was going to buy new bends, but actually had to use every little factory bend to clear everything and was the only routing that I could have taken. From this view it looks like I could have just taken a 90* bend after the cross member and then run in front of the tyre before going down the the muffler on the other side. But there just isn't the room as the diff would have hit it at full compression and the panhard cross member is deep on the left side.