More boring but necessary work going on.

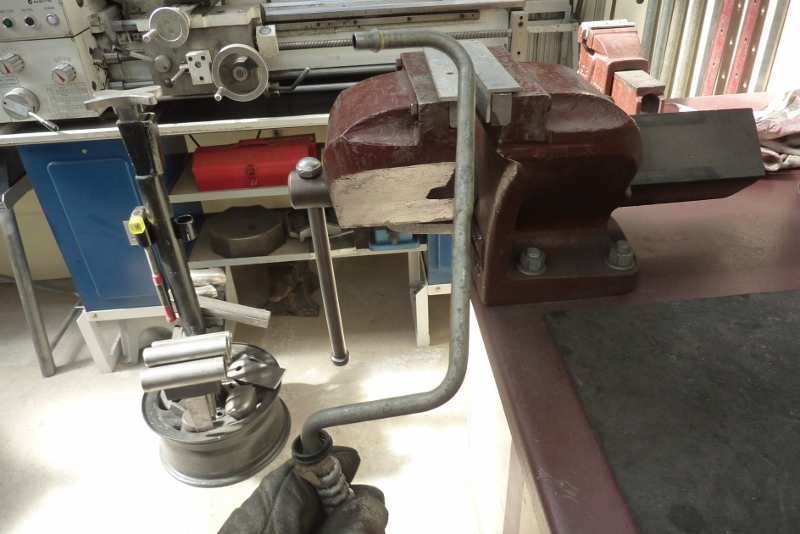

Doing some more plumbing. These are the 3/8" steel OEM transmission lines. I'm just showing one of the techniques for straightening bends I use. Just clamped between some aluminium angle.

I just push a little bit at a time, then move the line in as far as it will go into the jaws each time. The squared part of the line before the bend is where the factory separation clip goes.

This is what happens if you push to far between reclamping, You get secondary bends happening causing a dog leg.

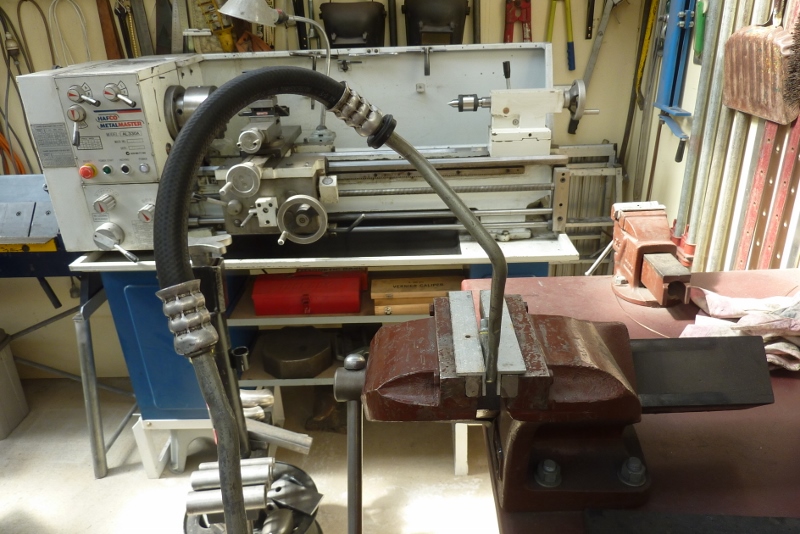

Once the bend is reduced to about 15-20*, I bend it straight in the middle of the jaws. Rotate and re clamp until it is straight all around.

Not show class, but more than good enough for what I am building. The bend was halfway between the squared part and the top bend.

The top bend was facing the wrong way. I could straighten it and then bend it the other way.

But when it has a long section before the next bend, I just twist it instead.

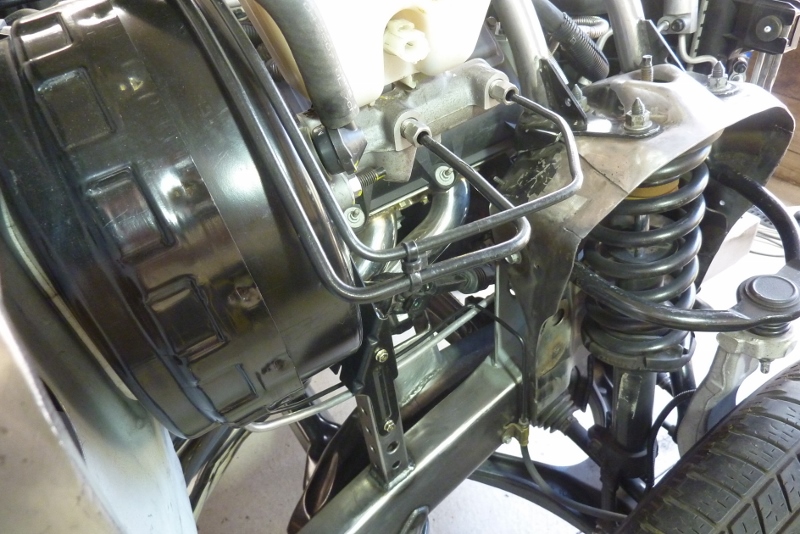

I now have the fuel lines run all the way as well as the transmission lines and the complete rear brake system. Still have all this to go though!

Thought I would share these hoses. They call them S hoses and are made especially for custom/universal applications.

They come in a variety of diameters and the FO on the end of the part number means these are for Fuel and Oil. They have cheaper water/vacuum versions, but you should never use them for fuel and oil!

I bought the 19mm-3/4" version to replace the power steering pump return line. You can see how much lower I have mounted the radiator than it was in the donor. It is closer as well.

I cut one of the bends off and fitted it. I was lucky with the donor top radiator hose as that just fitted right back on again. The bottom hose I had to shorten from both ends losing one of the flared end sections. I soaked the hose in boiling water to soften it and then quickly pushed it over a steel pipe slightly larger than the radiator outlet to expand it back up again. Then let cool.

Some of the more complex pipes that I was re-routing was this A/C line. I found it easier to make a template from wire first to see if I could use any of the factory bends in the new location rather than straightening it all out and starting again

This is the photo I took of the donor before pulling it apart so I knew where everything went! Even though I am making it look OEM, I try to neaten it a bit where I can.

This was I ended up with while also leaving as much room as possible for other things like the airbox and radiator overflow that was mounted on this side.

For working on the brake lines I used these tools. Rarely the centre two though as they both mar the plastic coating of the OEM lines.

I like these 3/16" line straighteners that I got from Eastwoods. I did however have to modify them so that the leading curve was at both ends rather than just one.

Just place the bend in the middle of the jaws and squeeze them hard. So long as the bend is less than 90*, they will work. Just stretch out those bends a bit first by hand that aren't.

That is the result of the bend gone between the remaining ones. I got a bit more improvement than this, if when squeezing hard, I hit the centre over the jaws with a nylon mallet while it was supported over some timber.

Lines that were shortened were re-flared with the Eastwoods tool. I was a brake mechanic many years ago and this is better than what we had back then.

A nice little trick I first saw 20 odd years ago, to separate ignition wires originally, was to use zip ties as a separation clip. First loosely loop over the two lines, then use a second zip tie around that tie between the two lines as a spacer.

Tighten the spacer zip tie fully before then tighten any remaining slack out of the other tie that is inside of it. One ready made line spacer. The line bends over the booster BTW were made with the first tool shown and the right bends were factory.

I have not done badly on using the OEM lines considering that I have 8.5" longer wheelbase than the donor Grand Cherokee and 7" of that is the front axle further forward of the firewall. Only the shortest line from the ABS pump to the nearest front wheel will have to be replaced if I want to keep the stock routing of going via the firewall first.