One of the rails had 2.5 degrees of twist in the end of the rail. So removed it by holding the rail in the press, bolting an old piece of channel to one of the existing holes in the frame where the twist was, then bouncing my whole body weight on the end of the channel. Came straight out.

Simple but effective.

This is the point where the front of the Grands engine and suspension cradle will bolt on underneath. It needed to be 226mm, so need to raise the frame to match.

Used a triangle calculator,

http://www.smex.net.au/Reference/TriangleCalc.htm to quickly workout how many degrees the bend, where it comes up from under the cab, needed to increase. Only needed just over 2 degrees which turned out to be a cutoff saw blade width.

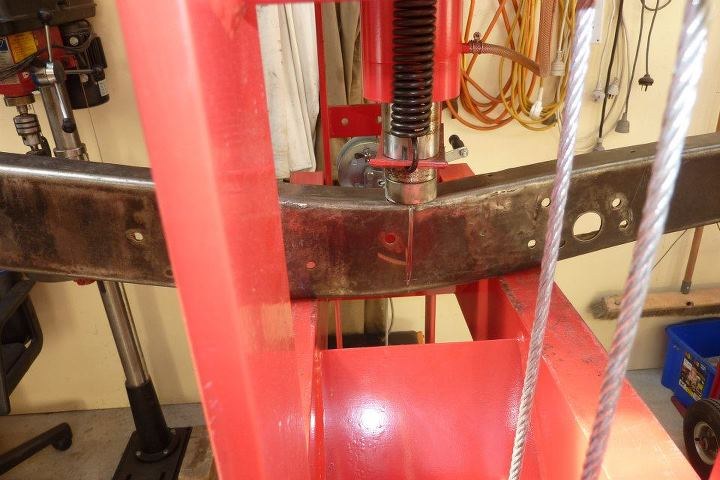

Line was scribed halfway in the curve and a right angle to it, then cut stopping an inch short of the flange. The reason I do it this way is that the bend in the lower flange will remain smoother and no obvious change will be seen. If you don't have a press, then can stop just before the flange and just pull the cut closed by hand.

The cut was fully bevelled so full penetration will take place when it is welded back up. Then placed in the press to close the gap. Needed very little pressure and didn't distort the web of the channel.

I tacked it while still in the press to stop it moving when the pressure was released.

Got it right where I wanted.

I have some rust repairs to do where the rail kicks up before the rear axle. Doesn't look too bad but there is a pin hole all the way through at one point.

Both rails have it in the exact same spot as dirt gathered behind the cross member and stiffening plate that was riveted in here. Only the stiffening plate itself suffered rust as well, but going to be replaced with a full length boxing plate anyway. I will cut this away, then do the kick up in the same spot before welding in a replacement section of frame.