Still more frame changes! I lowered the spare tyre winch cross member down so that the top was flush with the chassis after coming up with a better idea to make the bed floor sit flat on the chassis later on. Then I saw an opportunity to reduce the rear overhang as well, so off comes the cross member.

Making a brand new one from 100x50x5mm, (4"x2"x3/16"), RHS. I like to include the end caps for the frame ends at the same time. It increases the weld area of the cross member itself while reducing the total welds needed to adding a separate cap later on.

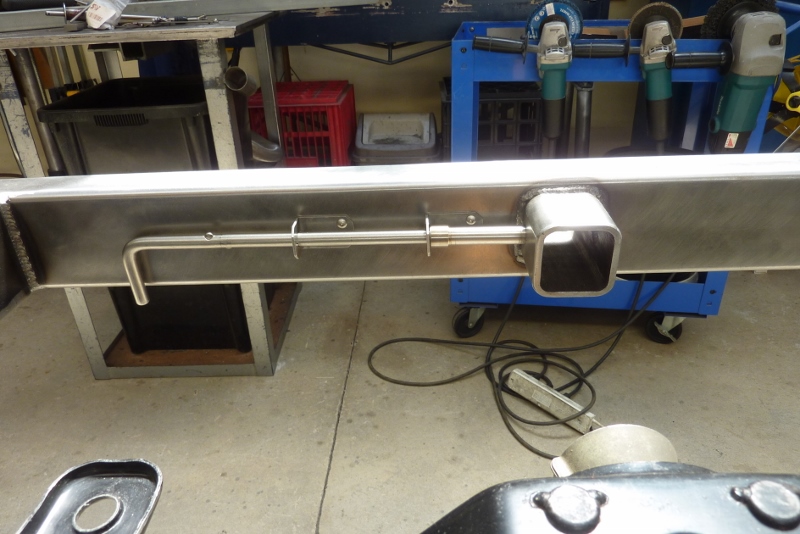

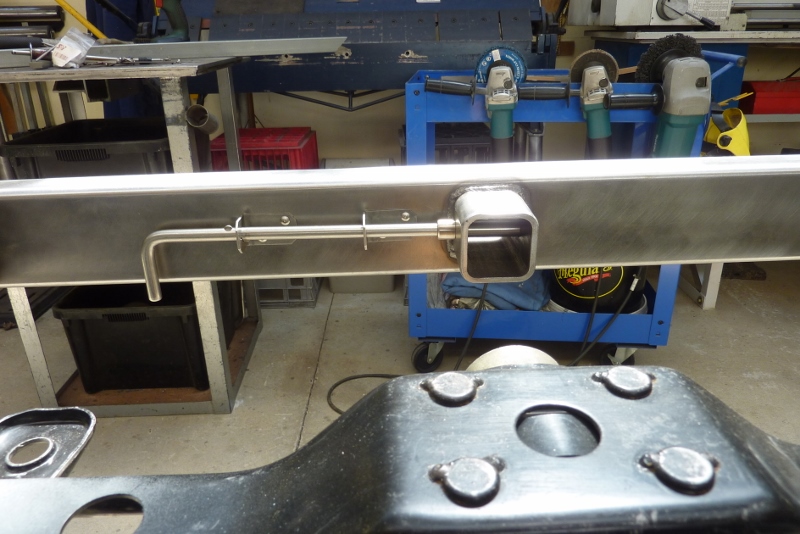

Adding a new receiver hitch into the cross member like before.

Bevelled the cross member as well and the receiver for best possible weld penetration when doing a flush fit.

Welding completed. I always take photos before any grinding in case the certifying engineer needs to know the quality of the weld afterwards.

All ground flush ready to install. If I leave it like the stock configuration, the rear cross member is seen below the tailgate.

So what is different? Well when I dropped the winch cross member to make it flush with the top of the chassis, I saw that by going back to the original width cross member, and raising the hitch receiver height slightly, I could move the cross member forward by 75mm, (3"), over the tyre to help reduce the rear overhang. Should make a more balanced look the side profile of the bed once it is made.

The hitch receiver now acts as one of the supports for the tyre.

I also came up with a way to connect my Jeep jack handle to the tyre winch. I made this adapter that fits the winch end.

The adapter then just slots into the jack handle shaft.

Now a bit of time on the lathe for the next part. This is 304 solid stainless bar.

The machined part is the new hitch pin. I am making a extended hitch pin from a 304 stainless steel gate drop bolt.

I bored the end of the hitch pin collar an interference fit so I could press it onto the drop bolt.

The drop bolt has tangs normally for holding the bolt up when you swing open your gates. Well I have made it so it locks the pin into the closed position. The tang has to pass through a slot in the bolt support with the handle horizontal and then it locks tightly once the handle is down.

To slide the pin out you just twist the handle up and side it back. The pin collar acts as a stop against one of the bolt supports so it cannot be pulled out too far. Simple but effective.

The jack shaft rests nicely on the hitch pin too when winching the tyre up and down. You can see now it would have been hard to access the hitch pin if it had not been extended off to the side.

I noticed some flex in the winch cross member so have reinforced it.