Rather than tacking with the mig like shown before, this time I thought I would try using the tig. I had the pedal adjusted to 50 amp max and mashed the pedal until it just got a gloss to it. Then moved to the next one. Worked even better as didn't have a tack to grind down afterwards.

Once it had naturally cooled I hit it with a hammer directly over the heated spot into the flat palm of my hand. The panel actually looks worse straight after heating as it has gathered up metal from around it. So you hit the spots with a sweeping strike in different directions away from it.

The high spot over the support was also worked the same way and is now gone. The reason this bonnet needed so much shrinking over the whole panel is I actually need less crown than before due to the wider bonnet that rises to the same overall height as before, but over a longer distance.

Thought I would add I little more high tech look under the bonnet as will have a modern engine. So going to use dimple die pressings. I tested the 3/4" size which was the largest I could fit inside the support, but didn't like the look. The 1" size shown was too big however.

So turned down the outside diameter on my lathe until it fitted. The flat area left around the dimple was still enough to do it's job of removing any distortion.

Can see the 3/4" and 1" pressing, (1.5" to the outside of the dimple), next to each other in the test piece. Just thought the bigger size had better proportions.

Halfway through drilling all the holes I want just using a step drill.

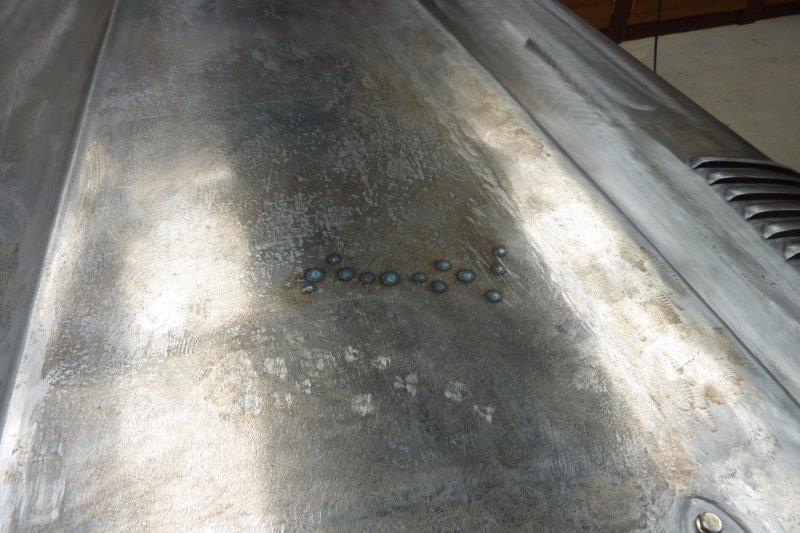

All drilled and pressed. I left the corners so it didn't flattened them out and they get distorted as well. Left the areas above the hinges and centre rib as think it looks better and what you find on aircraft as well where this technique comes from.

In place and bolted together on the Willys for the first time to see how it will all line up.

It sat a few millimeters low in the middle as the pressings would have flattened it slightly. So cut a piece of timber a bit long and carefully closed the bonnet over it to bend it upwards.

Now have a nice even height all the way along.

The gap isn't too bad either with only a slight bit of work needed towards the middle.

Something I need to address before moving on is I don't like how the lower bonnet edge comes up a bit short. In stock form it actually goes past the end of the guard but I wanted the rest of the bonnet to line up above the grille where the taper finishes.

View from the other side doesn't look good either.

So cut it and pulled the inner flange forward to line up with the end.

Placed some copper behind it and welded it up.

I like how it tapers towards the end now.

Next up is the front support. Won't be much I can use from the stock one!